|

Recovers the last error observed by the named encoder source. Either an Absolute Source Block or a Companion Source block could be referenced by this block.

Get Last Source Error

motohawk_flexenc_lib

| Parameter Field | Values | Comments/Description |

|---|---|---|

| Reference Source Name | Alpha-numeric text, quote enclosed | The name of the Absolute Source Block or Companion Source that this block is to recover the error from. |

The m-script motohawk_flexible_encoder_fault_enum enumerates the error value.

A source suffers a synchronization fault when the tracked position about the wheel does not match the calculated position. Tracked position is updated each time a source tooth is observed. Calculated position is updated each time a standard unique key is observed. It is checked once updated and this fault is issued when the two don't match and the source has previously achieved synchronization. The tracked position is not valid until the first calculated position has been observed and so synchronization faults are not possible until this first key match has occurred. This is important to note because the system may never achieve an initial synchronization if the key setup is wrong.

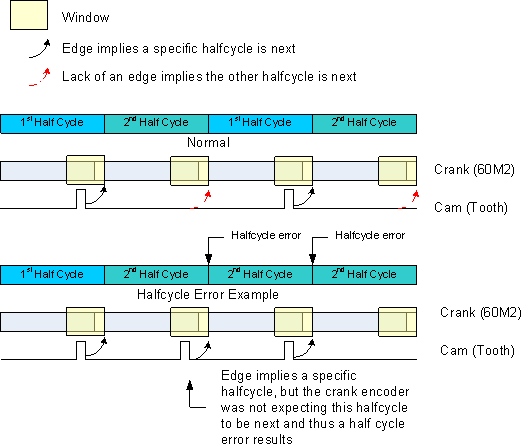

Only a source that rotates twice per cycle can observe a halfcycle fault. Such sources need to encode halfcycle in addition to wheel position. This fault indicates that the tracked halfcycle position does not match the calculated halfcycle position. Thus this fault is similar to a Synchronization Fault in that it relates to a mismatch between tracked and calculated position. The occurrence of this fault implies that the system has a problem with the halfcycle determination, which could be due to companion sensor setup or signal noise.

The Halfcycle Fault and the Synchronization Fault are mutually exclusive. Halfcycle position is only considered once it has been confirmed that the position about the wheel is correct.

The figure below illustrates a situation where a halfycle fault could occur. Window detection is being used. Normally the cam tooth is observed in every second window. If noise introduces a false tooth that happens to fall within the window then the system would consider it to be a real halfcycle marker. Now the tracked position does not match what the cam is telling the crank and so a halfcycle fault is flagged.

This link discusses state based detection, which can also cause this error.

A loss fault occurs when sufficient teeth have been observed on a companion sensor without having observed any teeth on the sensor under test. See Teeth Before Loss configuration. A loss fault can only be detected when a companion sensor exists because the system requires an alternate source of rotation detection to detect sensor loss.

An inversion fault requires a specialized inverted key to be specified. It is used to attempt to detect an inverted signal connection.

Issued when one source is not within the specified phase of another. A source is said to have suffered a phase error if its zero tooth (as defined by the Pattern Definition Physical Teeth entry of this source's referenced pattern) falls outside the window defined by Start Phase Window and End Phase Window. See example figures that illustrate this error.

An absent key fault or missed key fault results when an expected key is not observed. An absent key is detected by noting how many encoder source teeth have been observed since the last standard key was observed. Configured by the pattern in use by the named source.

Reserved for future support.

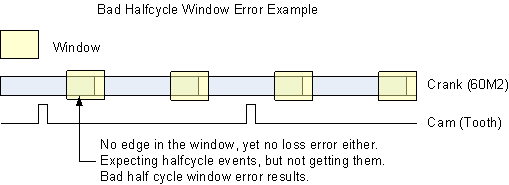

This errror is only observed when halfcycle window encoding is in use. Consecutive occurrences of this error suggests that the halfcycle window has not been correctly configured. It occurs when halfcycle events are being observed, yet none of these events are being observed within the window. Consider a tooth cam in a crank/cam system. This error would be flagged if, say, the tooth cam event was occurring 10 teeth before the crank's key, yet the window was only set to 8. The figure below illustrates.

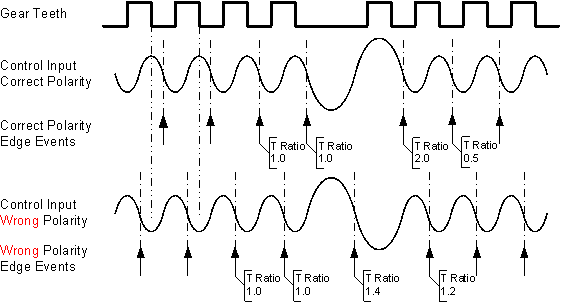

The observed period was less than half the previous period yet the tooth displacement were thought to be equidistant. This is considered a suspected noise event. It is not definitive because acceleration can also cause such a phenomena. Observing a Synchronization Fault subsequent to this fault validates that noise was observed and that the encoder had to re-synchronize. Only some runtime patterns support this fault.

This error refers to a "qualified" source observing synchronization event that fell outside the acceptance window specified by the application. This error can only be observed when the Synchronizer Slip feature is in use. It is only applicable to a small subset of encoder system configurations.

| Copyright 2010-2015 Woodward Corporation. All Rights Reserved. | Visit Us: mcs.woodward.com |