CCP CAN Protocol Handler Triggered

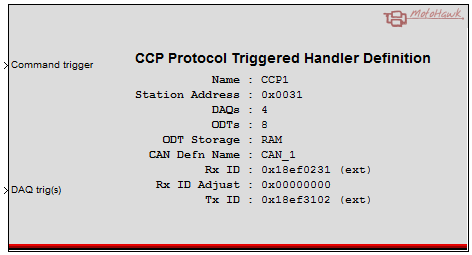

Use this MotoHawk™ block to enable handling a CAN Calibration Protocol (CCP) connection via CAN, with trigger inputs for Command Objects and Data Acquisitions.

Note: Do not place this block at the top level of a model, but at a subsequent lower level, if the Matlab version in use is 2007a or later, as this can cause triggering complications.

Block ID

CCP CAN Protocol External Trig

Library

MotoHawk_lib/CCP Slave

Description

Command trig: Connect a MotoHawk Trigger (or triggering from the CCP Triggers block) to the input to determine when CCP commands will be processed.

DAQ trig(s): Connect a vector of MotoHawk Trigger blocks to the input. These triggers determine the possible data acquisition rates (unique DAQ list rates).

Response to CCP Command packets is completed in the CAN interrupt in which they occur. For more information on CCP, see CAN Calibration Protocol.

Supported operations: upload calibrations, download calibrations, data acquisition, seed and key security.

Not supported: Flashing operations

Block Parameters

| Parameter Field | Values | Comments/Description |

|---|---|---|

| CCP Handler Name | Alpha-numeric text, single-quote enclosed | Enter unique name for handler instance. No special characters, such as spaces, dashes, commas (underscore allowed). |

| CCP Station Address (16-bit integer) | hex2dec('value') | Define the address that will used to communicate via the CCP Handler. On a CAN bus with multiple MotoHawk enabled modules, the Instrumentation Tool can communicate with each module by addressing their respective City ID’s (addresses). Therefore, each item on a bus MUST have a unique address. |

| CAN Definition Name | Alpha-numeric text, single-quote enclosed | Specify which CAN bus you want to use - as defined in the CANDefinition block. |

| Receive ID (CRO) | hex2dec('18ef0231') | Specify ID to be used for CCP communication of Command Request Object (CRO) |

| Receive ID Type (0=Std, 1=Ext) | 0 or 1 | Specify 0 for Standard (11-bit identifiers), 1 for Extended (29-bit identifiers) on the CAN bus. |

| Receive ID Mask | hex2dec('1FFFFFFF') | Specify Receive ID Mask |

| Transmit ID (DTO/DAQ) | hex2dec('18ef0231') | Specify Transmit ID for Data Transfer Objects and Data Acquisition |

| Transmit ID Type (0=Std, 1=Ext) | 0 or 1 | Specify 0 for Standard (11-bit identifiers), 1 for Extended (29-bit identifiers) on the CAN bus. |

| Total Number of DAQs (0-253) | 0-253 |

Set the number of Data Acquisitions for the CCP. |

| Total Number of Object Descriptors (ODT) per (DAQ) (1-253) | 1-253 | Set the number of Object Descriptors per Data Acquisitions for the CCP. |

| Store ODTs in NonVolatile (0=RAM, 1=EEPROM, 2-CAL) | 0, 1, 2 | Select choice of Storage for Object Descriptors |

| Send "Command Processor Busy" response prior to long memory writes | checkbox (default = unchecked) | The download of calibrations has the possibility of exceeding the allotted timeout for the DNLOAD command (25 ms). Some calibration tools are capable of extending this timeout if an initial "Command Processor Busy" response is received within the normal timeout period. Checking this option will enable the sending of a "Command Processor Busy" response as soon as a DNLOAD command is recieved where the data will be writing to EEPROM space. |

| Instrumentation Group | Alpha-numeric text | Defines Folder name and hierarchy for use by a suitable Instrumentation Tool. Use "|" character between folder names to delineate subfolder structure. |

Note:

Setting the "Command Processor Busy" checkbox to checked has been necessary when the combination of

ETAS INCA

and the MotoHawk target ECU565-128 are being used together.