Difference between revisions of "128-pin Module Family"

m (Added a link to the webstore for ECM-0565-128-0701-F) |

|||

| Line 71: | Line 71: | ||

== Part Numbers == | == Part Numbers == | ||

[[Image:pn_128.png]] | [[Image:pn_128.png]] | ||

| + | |||

| + | == Related Part Numbers == | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Part Number !! Description !! Available Online | ||

| + | |- | ||

| + | | 8923-1441 || Module Mounting Kit || | ||

| + | |} | ||

<br />'''BUY NOW'''<br/> | <br />'''BUY NOW'''<br/> | ||

Latest revision as of 08:20, 20 July 2021

Contents

- 1 Overview

- 2 FAQ

- 2.1 What's special about EST13 to EST16?

- 2.2 Can I use any of the Analogs with voltages higher than 5V

- 2.3 What EMC Rating does the PCM-128 have?

- 2.4 Why am I getting a ERROR_DRIVER_CONFLICT?

- 2.5 Where have DG5, 6,7,8 Gone?

- 2.6 Where is my KNOCK2?

- 2.7 Does 128-pin module have the option of software selectable pullup resistors

- 2.8 Why do I have an CECUServer:WriteECU- MWWriteECU error when calibrating a display value in MotoTune

- 2.9 What do the fault outputs of '0', '1', or '2' mean on the Digital Output or PWM block?

- 2.10 Is the Flexible Encoder Supported on the 128-pin module?

- 2.11 Is the SPD1 and SPD2 circuit the same on the 128-pin module?

Overview

Designed for large scale engine and powertrain (ECM) control, our 128 pin module delivers optimal flexibility for complex control strategies. This ECM is part of the Woodward’s family of electronic control modules with over 1 million units successfully deployed in the field. Built on the proven MPC565 processor, the onboard floating point unit and high clock frequency allow software to be developed in shorter times. Dual CAN 2.0B datalinks ensure interoperability with other vehicle systems. Typical applications include general rapid prototyping, peak/hold fuel injection, and 12 cylinder sequential engines.

Link to MotoHawk help for PCM128

Important: The ECM-565-128-0704 and the ECM-565-128-1001 are NEW 128 pin modules. There are hardware changes and further, these new modules require a NEWER MotoHawk.

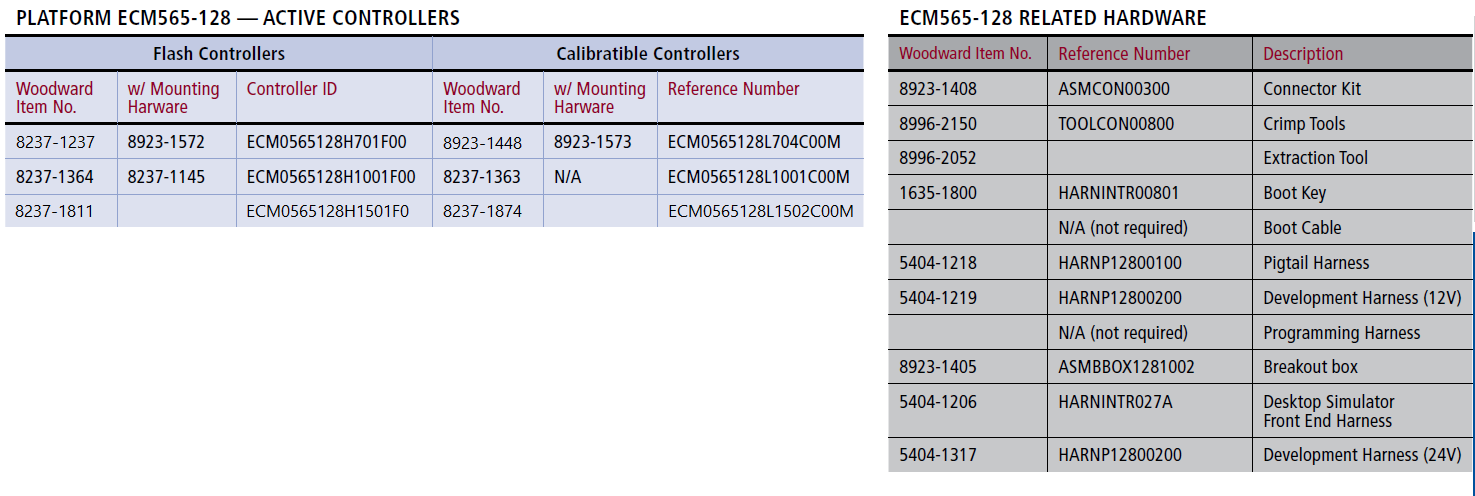

See Product Guide for Active Part Numbers and Related Hardware (Connectors, Harnesses, Bootkey..).

Datasheets

ECM-0565-128-0701-C Datasheet (36320)

- Resource Descriptions, Pinouts, etc., for the ECM-0565-128-0701-C Module

- MY07 LoVol Hardware is no longer available.

ECM-0565-128-0701-F Datasheet (36321)

- Resource Descriptions, Pinouts, etc for the ECM-0565-128-0701-F Module

- MY07 HiVol Hardware has limited supply.

- BUY NOW 8923-1572 ECM-0565-128-0701-F with mounting hardware

ECM-0565-128-0702-C Datasheet (36355)

- Resource Descriptions, Pinouts, etc., for the ECM-0565-128-0702-C Module

- Also covers P128L0705, which is the same as the 0702 hardware, but a newer firmware loader is used and a change to the SPD2 output is present. There are no software implications to using 0705 over 0702.

- Also covers P128L0707, which is the same as the 0705 hardware, but on obsolete FET was changed. There are no software implications to using 0707 over 0705.

- MY07 LoVol Hardware is no longer available.

ECM-0565-128-0704-C Datasheet (36371)

- Resource Descriptions, Pinouts, etc., for the ECM-0565-128-0704-C Module

- MotoHawk 2010bSP0 or higher is Required for the ECM-0565-128-0704-C Module

- Also covers P128L0706, which is the same as the 0704 hardware, but on obsolete FET was changed. There are no software implications to using 0706 over 0704.

- MY07 LoVol Hardware is no longer available.

ECM-0565-128-1001-C/F Datasheet (36368)

- Resource Descriptions, Pinouts, etc., for the ECM-0565-128-1001-C/F Module

- MotoHawk 2010bSP0 or higher is Required for the ECM-0565-128-1001-C/F Module

- MY10 Hardware is no longer available.

Hardware Features

- Microprocessor: MPC565, 56MHz

- Memory: 1M Flash, 548K RAM, 8K Serial EEPROM,

- 64Kx8 Parallel EEPROM

- Operating Voltage: 9-32VDC

- Operating Temperature: -40° to 105° C

- Sealed connectors operable to 10ft submerged

Inputs

- 30 Analog Inputs

- 4 Low Frequency Discrete Inputs

- 4 VR Frequency Inputs

- 2 Wide Range O2 Sensor Inputs

- Dual Lambda Sensor Interface

- 2 Dual Sensor Wide Band Knock Detectors

Outputs

- 6 3A /1A Peak/Hold Injector Drivers

- 6 7A/3A or 3A/1A Peak/Hold Inj. Drivers

- 16 TTL Level Ignition System Outputs

- 10 3A Low Side PWMs

- 1 1.5A Tachometer Output

- 2 5A H-Bridge PWMs

- 1 10A H-Bridge PWM

- 1 Relay Driver (Main Power)

Datalinks

- 2 CAN 2.0B Channels

- 1 ISO 9141 Channel Note: ISO9141 Hardware is not supported in MotoHawk Software.

- (KWP2000/HWP2000, 10.4kbps)

- 1 RS485 Channel

Part Numbers

Related Part Numbers

| Part Number | Description | Available Online |

|---|---|---|

| 8923-1441 | Module Mounting Kit |

BUY NOW

8923-1572 ECM-0565-128-0701-F with mounting hardware

Additional Information

There are two main types of PCM128

Hi-Vol

- 1024K Flash

- NO Parallel EEprom (PROD style)

- 32K Serial EE

- 36K RAM

Lo-Vol

- 1024K Flash

- Parallel EEProm (DEV Style)

- 32K Serial EE

- 1024K RAM

MY10 Modules

Due to the EGO IC going EOL, it was required to release new hardware variants of the 128-pin ECUs. These are the ECM-0565-128-1001C/F and the ECM-0565-128-0704C modules. See the module datasheet for specific module details.

MotoHawk 2010bSP0 or higher is required for these ECUs.

The -0704 version is the same as the -0702C version, except with the EGO 1&2 inputs replaced by AN31-34. There is not a corresponding 'F' (PROD) -0704 module because the Flash (PROD) modules did not have the EGO IC.

Changes: ECM-0565-128-1001 (C/F)

- H2 and H3 h-bridges are depopulated

- LSU 4.2 on second UEGO input replaced by LSU 4.9

- AN18 pullup changed to 10k

- EGO1&2 depopulated

- AN31-34 populated

- AN34 changed to 60.4k

- EST9-12 converted to low-side Lamp/LED drivers

ECM-0565-128-0704C

- EGO1&2 depopulated

- AN31-34 populated (AN31,32 are 1M pull-down, AN33,34 are 1k pull-up)

MY15 Modules

Due to the H1 h-bridge IC going EOL, it was required to release new hardware variants of the 128-pin ECUs. H1 will no longer be functional (H2 and H3 were removed in MY10) because the H1 h-bridge IC is depopulated.

Fault Reporting

LSOs or H-briges

These outputs use a Fault reporting of 0 (ok), 1 (fault) or 2 (indeterminate) that is enabed as a checkbox in the PWM or Discrete Ouptut MotoHawk block. This checkbox creates a fault output port on the block that can be read by the application.

- A fault status of ‘0’ means that the module has read the error status and can determine that a short or open fault is not occurring.

- A status of ‘1’ indicates that the driver has detected a short (to battery or ground) or open fault.

- A fault status of ‘2’ indeterminate means that either it is not possible to determine in the current state whether there is a fault or whether the output is ok, or that the OS has not had an opportunity to detect a fault. A fault status of ‘2’ will also be reported in the case that the fault detection is not supported on the chosen pin (ex. on the injector pins).

The driver can report faults of open circuit, short to ground, and short to battery, but not simultaneously. For example when the load is ON an open circuit cannot be detected – an open can only be detected when the discrete output is off. Similarly, short to battery cannot be detected when the LSO is off. The ‘2’ means indeterminate and means that either the OS has not had opportunity to detect a fault or cannot determine if a fault condition exists. For example, when the discrete output is off and there is not an open circuit, the OS cannot be certain there is not a battery shorted condition and will report a ‘2’. The fault output will be ‘1’ when a fault condition is detected, and a ‘2’ otherwise. The output will not report a ‘0: OK’.

For the LSO's the pre-FET driver is the TPIC IC. This device is polled periodically for fault information. However, the TPIC does not latch the fault infomormation. So, the fault needs to be present when polled before it will be seen. The fault reporting is the same whether the output is driven by a discrete or PWM block. However, the state of the output also affects the fault detection. Open faults can be detected when the output is OFF and short faults can be only detected when the output is ON. Therefore, if the output is switched with a PWM the switching may cause a difference in fault behavior as compared to a discrete ON/OFF where the output is potentially in one state for a longer period of time.

Injector and ESTs

The diagnostics for the injector pins are only supported (in hardware and software) when the outputs are being driven by PSP output blocks (Injector or spark blocks such as Injector Sequence or Multiple PSP).

The fault status from the discrete output block or PWM block when the selected pin is an INJ or EST output will always read a ‘2’. Fault detection of the Injector and ESTs when not driven by PSP output is not supported.

INCA and the 128-pin module

Using INCA to download or upload large calibration tables (maps) can be very resource intensive on the 128-pin ECU. The CPU idle can drop below 10% and cause the application monitor to halt the application, or if the application monitor is not enabled the CPU can be starved for task execution and reset. This is a known issue and is due to the fact that the calibration is written directly to the EEPROM and EEPROM writes are slow.

There was an improvement implemented in MotoHawk 2013a where the watchdog is service during slow memory writes to help prevent the reset described above. If you are experiencing resets while uploading/downloading large calibration sets we recommend using MotoHawk 2013aSP0 or higher.

Additional Suggestions are also below:

1. Use MotoHawk 2013aSP0 or greater. There were also improvements to the CCP handling implemented in 2010a which may benefit this issue.

2. Check the 'Send Command Processor Busy" option in the CCP handler block. This can alert the calibration tool that the ECU is busy writing to EEPROM and to wait.

3. Make sure the CCP block is Idle triggered. There are two CCP blocks - one has external triggers. Use the block with the external triggers and trigger it from Idle.

4. Set the Optimized Up/Download option in INCA to Yes.

5. Try increasing the foreground task and idle task stack in the target definition block.

6. There is also a Starvation Timer block that allows the application designer to set the amount of task starvation time allowed before the watchdog resets the processor. The application developer would want to set this for what makes sense for the application (ex. in the event of an infinate loop), but extending this time may allow additional time for calibration with INCA.

Knock

The DEV (Low Volume) versions of the ECM-565-128 feature two knock channel inputs, via the Prosak knock chip. The modulator clock frequency for the Prosak on the 128 pin ECU is 4.67 MHz.

FAQ

What's special about EST13 to EST16?

- These pins have stronger LowSide Drivers and can sync higher current

- The hardware can be configured as PUSH_PULL or LOW_SIDE drive

- Current MotoHawk sets the DriverMode to LOW_SIDE for DIO, OneShot and to PUSH_PULL for PWM.

- The Hi-Vol PCM128 does not have pull-up transistors, so technically cannot be configured as PUSH_PULL but the polarity remains active high.

- When instantiating from ControlCore as a LOW_SIDE it makes them active low instead of active high.

Tips

- Think of EST1-12 and EST13-16 as two separate banks

- Avoid mixing Behaviours within a bank where possible, as it can potentially restrict DriverModes and Diagnostic Capability.

Can I use any of the Analogs with voltages higher than 5V

The ADC would saturate at 5V, so your reading at 5V and higher would be full counts. It is not recommended to use voltages higher than 5V with any of the analogs with pull up resistors. The analongs with weak pull downs (PD of 220k or 51.1k) can be used with 24V.

What EMC Rating does the PCM-128 have?

We have CE mark on the LV models only and E mark on the HV models only. Both models were also tested to the SAE J1113 standards.

Why am I getting a ERROR_DRIVER_CONFLICT?

Where have DG5, 6,7,8 Gone?

You will get "Hardware Not Supported" if you use a Low-Vol. These resources are consumed as part of the KNOCK2 device.

Where is my KNOCK2?

The Hi-Vol only has KNOCK1

Does 128-pin module have the option of software selectable pullup resistors

No, the pullups are not configurable. Selecting the 'Strong' vs 'Weak' pullup in the Encoder Defintition block does not change any value.

An external 2.2k pullup resistor may be needed with open-collector type crank and cam sensors.

Why do I have an CECUServer:WriteECU- MWWriteECU error when calibrating a display value in MotoTune

This error will occur if a model built for a 128-pin ECU is programmed into a MY10 ECU, and the version of MotoHawk is too old to support the new model hardware. MotoHawk 2010bSP0 or higher is required for ECM-565-128-1001C/F or ECM-565-128-0704C.

What do the fault outputs of '0', '1', or '2' mean on the Digital Output or PWM block?

- A fault status of ‘0’ means that the module has read the error status and can determine that a short or open fault is not occurring.

- A status of ‘1’ indicates that the driver has detected a short (to battery or ground) or open fault.

- A fault status of ‘2’ indeterminate means that either it is not possible to determine in the current state whether there is a fault or whether the output is ok, or that the OS has not had an opportunity to detect a fault. A fault status of ‘2’ will also be reported in the case that the fault detection is not supported on the chosen pin (ex. on the injector pins).

I will use the LSO’s as an example. The LSOs use a PreFET driver IC called a TPIC to provide the diagnostic information. Faults of open circuit, short to ground, and short to battery can be detected, but not simultaneously. For example when the load is ON an open circuit cannot be detected – an open can only be detected when the discrete output is off. Similarly, short to battery cannot be detected when the LSO is off. The ‘2’ means indeterminate and means that either the OS has not had opportunity to detect a fault or cannot determine if a fault condition exists. For example, when the discrete output is off and there is not an open circuit, the OS cannot be certain there is not a battery shorted condition and will report a ‘2’. The fault output will be ‘1’ when a fault condition is detected, and a ‘2’ otherwise. The output will not report a ‘0: OK’.

How are diagnostics for injector pins supported? The fault output port always reports a '2' Indeterminate

The diagnostics for the injector pins are only supported (in hardware and software) when the outputs are being driven by PSP output blocks (Injector blocks). The fault status from the discrete output block when the selected pin is an INJ Output will always read a ‘2’ in this case.

Is the Flexible Encoder Supported on the 128-pin module?

No, the Flexible Encoder requires enhanced TPU or eTPU. The flexible encoder cannot be supported on the 128-pin's TPU - the hardware is not capable of this.

Is the SPD1 and SPD2 circuit the same on the 128-pin module?

Originally the inputs were the same, but the SPD2 input was revised as part of the MY07 model roll. The RF cap, the Hall RC and the threshold were increased on SPD2 to provide more filtering. This explains why the SPD2 signal has a much slower rise time when compared to SPD1. Note these changes:

SPD1 Input Impedance: 51.1 KOhm pullup to VCC

SPD1 Anti-aliasing Filter: 1 pole at ~16usec

SPD1 EMC Bypass Cap: 1 nF

SPD2 Input Impedance: 10 KOhm pullup to VCC

SPD2 Anti-aliasing Filter: 1 pole at ~22usec

SPD2 EMC Bypass Cap: 47 nF