SECM112

PRELIMINARY

Contents

Module

Overview

The ECM-OH is part of the engine management system for on-highway applications, which can include L6 4-stroke CNG intercity transit applications, L6, 4-stroke LNG intercity transit applications, and L4 4-stroke commercial vehicle applications. The module is capable of full authority digital engine control (FADEC) consisting of fuel, spark, and air delivery to the engine. Additional inputs and outputs are available to control other system functions, as defined by software. This unit provides 112 connector pins with inputs, outputs, and communications interfaces that support a wide variety of applications.

The ECM-OH features two microprocessors in one rugged production intent housing. The module contains a main MPC5644 120Mhz processor along with a S12G fixed point processor, which can provide question-answer type challenge to the main processor. Both micros are connected on CAN1.

The ECM-OH is part of the MotoHawk Control Solutions ControlCore® family of embedded control systems. The ControlCore operating system, MotoHawk® code generation product, and MotoHawk’s suite of development tools enable rapid development of complex control systems. Application code for both processors is developed in MotoHawk which allows the application developer to create applications directly in Simulink and build with a one step 'CNTL-B' build. The two controllers act like separate controllers in terms of programming. Then, the program can be flashed onto the micro using Woodward's MotoTune, Toolkit, or through industry standard 3rd party tools via xCP, or ISO15765.

Calibration can be done with Woodward's MotoTune or Toolkit or with industry standard 3rd Party tools through xCP.

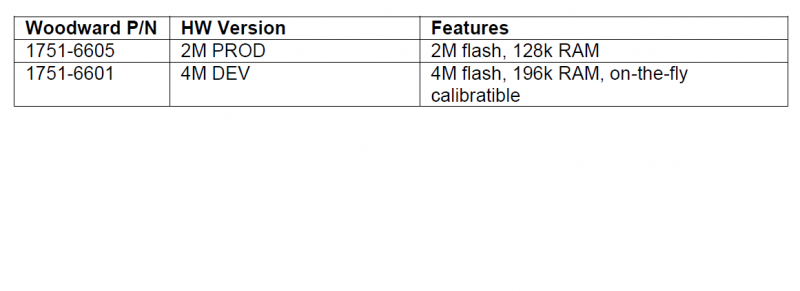

Each controller is available in ‘F’ (Flash) or ‘C’ (Calibratible) versions. Flash modules are typically used for production purposes. Calibratible modules are typically for prototyping/development only; they can be calibrated in real time using MotoTune, ToolKit, or industry standard 3rd party tools via xCP.

Power Requirements

All versions of the ECM-OH Control require a voltage source of 8 to 32Vdc (12Vdc or 24Vdc nominal).

MotoHawk Requirements

MotoHawk 2012bSP0 or higher is required for ECM-OH.

Compilers

Main Micro: Green Hills 4.2.4 or GCC PowerPC eabi SPE 4.6

Auxillary: Freescale CodeWarrior 4.6

Control Features

Standard features common to both models are:

- 2 engine speed inputs: camshaft and crankshaft speed (software configurable for variable reluctance (VR) magnetic pickup sensor or Hall effect proximity sensor inputs)

- Up to 6 frequency inputs (some share analog resources)

- Up to 33 analog inputs

- 3 switch inputs

- 2 HEGO sensor inputs

- 2 LSU sensor inputs (also known as UEGO sensors)

- 2 knock sensor inputs

- 3 transducer power outputs providing +5V (350mA & 100mA) and +12V (100mA)

- 2 H-bridge driver outputs providing 10A and 5A drive capability and current sense feedback

- 6 Injector drivers providing software configurable peak and hold current levels (up to 7A/2A)

- 6 ignition coil drivers

- MPRD (Master Power Relay Driver) low side output

- TACH low side output

- 16 low side output drivers (1 with current sense feedback)

- 3 CAN (Controller Area Network) communications ports

- 4K-byte serial EEPROM for tunable parameter storage

- Auxiliary micro with 128k of flash, 8k of RAM, 4k of EEPROM

Inputs

Analog Inputs (AN1 – AN34)

There are 34 analog inputs on the ECM-OH. The analog inputs have either a pull-up resistor as shown in Figure 2-12, or a pull-down resistor as shown in Figure 2-13. Five analog inputs have a software pull-up or pull-down selection via calibration. AN21 & AN30 share a common control line for the 1k or 11k selection, designed for EGT sensor diagnostics. All the analog inputs have a single-pole filter with a 1 ms time constant, except for Analog Input 5, which is reserved for a MAP (Manifold Absolute Pressure) sensor and has a 0.24 ms time constant.

Crank and CAM Inputs

The Cam and Crank (CNK) inputs are used to detect engine speed and angular position relative to TDC. The ECM-OH has CAM and Crank sensor inputs that can be connected to either a variable reluctance magnetic pick-up sensor (VR-MPU), or to a Hall-effect proximity switch. Each type of input has dedicated connector pins. See the ECM-OH datasheet for additional detail.

Digital Inputs

The ECM-OH has 8 Discrete Inputs. Some may be used as switch inputs, others support frequency measurement.

Lambda Sensor Unit (UEGO) Inputs

The ECM-OH control has two LSUs (Lambda Sensor Units), also known as UEGO (Universal Exhaust Gas Oxygen) inputs, which interface with Bosch LSU4.9 wide range oxygen sensors (Lambda sensors). The lambda-sensor(s) works in conjunction with the on-board Bosch CJ125 ASIC(s) to provide continuous regulation of for a sensor in the range of = 0.65... (air). The LSU inputs allow the ECM-OH to continuously regulate the engine air-to-fuel ratio, thus controlling the percentage of exhaust pollutants during the combustion process.

Knock Sensor Inputs

The ECM-OH supports two Knock Sensor inputs.

Outputs

Low-side Outputs (LSO)

The ECM-OH control has 16 low-side outputs (LSOx & SPK8) that can be used as Boolean outputs for driving relays, or some as PWM outputs. LSO1 and LSO2 are also designed to drive the heater coil on a LSU sensor. Some low-side outputs are provided with freewheeling diodes (internal to the ECM-OH through DRVP or BATT) to suppress the back EMF caused by inductive loads. See the ECM-OH datasheet for low-side output capabilities and characteristics.

Injector Outputs

The ECM-OH control has 6 injector outputs, each capable of driving either low or high impedance injectors. Each injector output can be used as a Boolean output, a PWM output, or as a synchronous or periodic peak and hold injector output.

Spark Outputs

The ECM-OH has 6 IGBT ignition coil drivers each capable of delivering up to 10A of peak dwell current.

H-bridge Outputs

The ECM-OH control has two H-bridge outputs that can be used to drive electric motors, e.g., butterfly throttle valves. H-bridge output 1 is capable of driving up to 10A peak (5A average) in either direction, while H-bridge 2 can drive up to 5A peak (2.5A average). The H-Bridge outputs are provided with freewheeling diodes (internal to the ECM-OH through DRVP) to suppress the back EMF caused by inductive loads.

The following are shared between the main and s12G cores:

Analog inputs: AN01-05, AN16, AN17, AN18, AN24, AN31, VCAL, KEYSW

Digital inputs: VR1/DG1 (after mux), DG3, DG4, DG5, DG8, Wake-up (on XIRQ) from main core, reset from main core, main core status

Comms: CAN1

Outputs: H1 enable, H2 enable, MC33810 enable, NCV enable, VR1/DG1 mux disable, VR2/DG2 mux disable, MPRD disable, main core reset, reset main core status, main core interrupt, CAM VR mode select, CAM VR threshold PWM, AN20 PU select, AN24 PU select, AN31 PU select, DG3 PU select

The CAM VR mode select, CAM VR threshold PWM, AN20 PU select, AN24 PU select, AN31 PU select, DG3 PU select can be configured by the main core via SPI.

Communications

CAN

The ECM-OH has three 2.0B CAN ports for distributed I/O, distributed control, and Human Machine Interface (HMI) purposes.

MotoHawk Target Cross Reference

The MotoHawk Target Cross Reference shows which IO on the ECM-OH hardware is supported by which behavior (blocks). There are charts showing behavior vs pin as well as pin vs behavior. This is the software help document for the module.

Recovering the ECM-OH

Occationally, errors in programming may require that the module be recovered with a boot key or boot sequence.

See Boot Key Recovery for more detail on how to recover the module.

Important: Remove the ECU from all controll connections before attempting to recover the module.

The ECM-OH is different in that it has two microprocessor cores, the Main Core and the Auxillary S12G. The processors are connected on CAN1, so it is important that the baud rate of both processors on CAN1 be the same. The processors must also communicate with MotoTune on different city-id's.

Recovering the Main Processor

The main processor can be recovered with a boot key on pin DG8. The boot key provides a 555Hz, 0-Vbatt, 50% duty cycle square wave on the STOP pin (pin E) of the 10-pin hub. This signal can then be wired to DG8.

Alternatively, the main processor can be recovered with the following sequence on the analog inputs:

AN3: Pull to +5V

AN4: Pull to +5V

AN16: Pull to GND

AN17: Pull to GND

AN18: Pull to +5V

Recovering the S12G Auxillary processor.

The S12G cannot be recovered with a boot key. A boot sequence on the analog inputs of the S12G is required to recover it.

AN3: Pull to +5V

AN4: Pull to +5V

AN16: Pull to +5V

AN17: Pull to GND

Notes:

If you are recovering the S12G core of the ECM-OH, you must first program an application into the Main Core that sets CAN1 to be 250kbps. Battery must be toggled before powering up the S12G in Boot mode.

Use the following MotoServer Port Configurations when connecting with the ECU. These are the default hardboot settings. ECM-OH main: 250kbps on CAN-1, City ID 0xB (11) S12G: 250kbps on CAN-1, City ID 0x81 (129)

The Pre-PV and PV units will ship with a sample application that will connect at 500k on PCM-1 (City-ID 11) or PCM-2 (City-ID 12. Recovering either microprocessor will force it back to it's default hardboot baud rate of 250kbps. So, you must reprogram the other microprocessor with an application to change it to 250kbps.