Difference between revisions of "SECM70"

m (refinement) |

m (Updated the Product Summary) |

||

| Line 35: | Line 35: | ||

vehicles. The SECM70 control is programmed to meet the specific needs of the | vehicles. The SECM70 control is programmed to meet the specific needs of the | ||

prime mover and its driven load. | prime mover and its driven load. | ||

| + | <br/><br/> | ||

| + | At the heart of the SECM70 control is a powerful 32-bit ST SPC563M64 | ||

| + | microprocessor that runs Woodward’s ControlCore operating system. Application | ||

| + | programming is accomplished via Woodward’s MotoHawk application software | ||

| + | tool. MotoHawk is a rapid controls system development tool that allows controls | ||

| + | engineers to quickly create controls software directly within Simulink diagrams, | ||

| + | which run on any MotoHawk-enabled electronic control modules. Application | ||

| + | developers work directly in the Simulink environment and with a one-step build | ||

| + | are able to go from an application model to a file that can be programmed directly | ||

| + | into Woodward production hardware. MotoHawk provides a high-level | ||

| + | programming environment for users who have control systems expertise but | ||

| + | don’t necessarily have specific embedded programming skills. Once the | ||

| + | application program has been generated and loaded into the SECM70 control via | ||

| + | the CAN port, the user can view variables and tune the control using an | ||

| + | appropriate service interface tool such as [[ToolKit_Custom_HMI_Software|Woodward's Toolkit]] or [[MotoTune]]. | ||

| + | Connection to other devices, such as a diagnostic tool, is accomplished by | ||

| + | means of other CAN ports available on the control. The desired information flow | ||

| + | is programmed into the control via [[MotoTune]] or [[ToolKit_Custom_HMI_Software|ToolKit]]. | ||

| + | <br/><br/> | ||

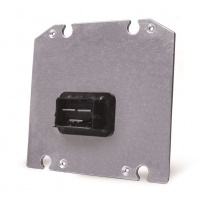

| + | The SECM70 control consists of a single rigid printed circuit board attached to an | ||

| + | aluminum housing using thermal adhesive, which is then closed and sealed with | ||

| + | an aluminum cover. Connections to the control are made via a single 70-pin | ||

| + | automotive-style sealed connector. The control can be mounted directly to the | ||

| + | engine or frame using vibration isolators which are available pre-installed on the | ||

| + | control or separately. | ||

== Frequently Asked Questions/Topics == | == Frequently Asked Questions/Topics == | ||

Revision as of 09:02, 6 March 2015

Contents

ECM-5634M-70

Hardware Features

- 70-Pin platform

- Microprocessor: ST SPC563M64, 80 MHz

- Memory: 1.5 M flash, 94 K RAM, 16 K serial EEPROM

- Operating Voltage: 8–32 Vdc, 36 V (jump start), 5.5 V (crank)

- Operating Temperature: –40 to +105 °C

Inputs:

- VR or digital crank position sensor

- Digital cam position sensor

- Up to 14 ananlogs

- Up to 5 digital (4 switch, 1 speed)

- up to 2 switch-type oxygen sensors

- Optional wide-range oxygen sensor

- Up to 2 knock sensors

Outputs:

- 6 high-impedance injector drivers (up to 4 low impedance injector drivers)

- Up to 8 electronic spark-triggers for smart injection coils

- 9 low-side drivers

- 3 lamp drivers

- 1 main power relay driver

- up to 2 H-bridge drivers

- Optional 3-phase brushless DC motor driver

- 1 sensor supply (5V)

Communications:

- 2 CAN 2.0b channels

(INCOMPLETE)

Product Summary

The SECM70 control platform fits a variety of applications, including gasoline and

natural gas engines for power generation, forklifts, lift trucks, and on-highway

vehicles. The SECM70 control is programmed to meet the specific needs of the

prime mover and its driven load.

At the heart of the SECM70 control is a powerful 32-bit ST SPC563M64

microprocessor that runs Woodward’s ControlCore operating system. Application

programming is accomplished via Woodward’s MotoHawk application software

tool. MotoHawk is a rapid controls system development tool that allows controls

engineers to quickly create controls software directly within Simulink diagrams,

which run on any MotoHawk-enabled electronic control modules. Application

developers work directly in the Simulink environment and with a one-step build

are able to go from an application model to a file that can be programmed directly

into Woodward production hardware. MotoHawk provides a high-level

programming environment for users who have control systems expertise but

don’t necessarily have specific embedded programming skills. Once the

application program has been generated and loaded into the SECM70 control via

the CAN port, the user can view variables and tune the control using an

appropriate service interface tool such as Woodward's Toolkit or MotoTune.

Connection to other devices, such as a diagnostic tool, is accomplished by

means of other CAN ports available on the control. The desired information flow

is programmed into the control via MotoTune or ToolKit.

The SECM70 control consists of a single rigid printed circuit board attached to an

aluminum housing using thermal adhesive, which is then closed and sealed with

an aluminum cover. Connections to the control are made via a single 70-pin

automotive-style sealed connector. The control can be mounted directly to the

engine or frame using vibration isolators which are available pre-installed on the

control or separately.

Frequently Asked Questions/Topics

Can I diagnose PWM EST outputs?

Due to the nature of the hardware, EST diagnostics are only available when driven as a sequence and not as a PWM.

The ESTs have a caveat that certain groups must not turn off at the same time as there is shared diagnostic HW.

The groupings where you should avoid turning off at the same time are:

EST 1,2

EST 3,4

EST 5,6,7,8