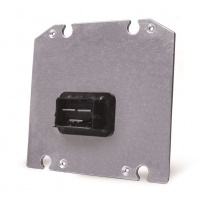

SECM70

From MotoHawk

Contents

ECM-5634M-70

Hardware Features

- 70-Pin platform

- Microprocessor: ST SPC563M64, 80 MHz

- Memory: 1.5 M flash, 94 K RAM, 16 K serial EEPROM

- Operating Voltage: 8–32 Vdc, 36 V (jump start), 5.5 V (crank)

- Operating Temperature: –40 to +105 °C

Inputs:

- VR or digital crank position sensor

- Digital cam position sensor

- Up to 14 ananlogs

- Up to 5 digital (4 switch, 1 speed)

- up to 2 switch-type oxygen sensors

- Optional wide-range oxygen sensor

- Up to 2 knock sensors

Outputs:

- 6 high-impedance injector drivers (up to 4 low impedance injector drivers)

- Up to 8 electronic spark-triggers for smart injection coils

- 9 low-side drivers

- 3 lamp drivers

- 1 main power relay driver

- up to 2 H-bridge drivers

- Optional 3-phase brushless DC motor driver

- 1 sensor supply (5V)

Communications:

- 2 CAN 2.0b channels

(INCOMPLETE)

Product Summary

The SECM70 control platform fits a variety of applications, including gasoline and natural gas engines for power generation, forklifts, lift trucks, and on-highway vehicles. The SECM70 control is programmed to meet the specific needs of the prime mover and its driven load.

Frequently Asked Questions/Topics

Can I diagnose PWM EST outputs?

Due to the nature of the hardware, EST diagnostics are only available when driven as a sequence and not as a PWM.

The ESTs have a caveat that certain groups must not turn off at the same time as there is shared diagnostic HW.

The groupings where you should avoid turning off at the same time are:

EST 1,2

EST 3,4

EST 5,6,7,8