|

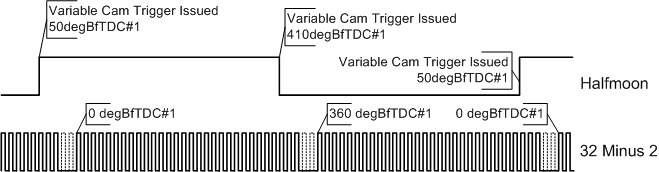

A half moon cam phaser, when used for variable cam phase control, offers the potential for a position report on each observed edge. Most typically the cam sensor and pattern arrangement on such systems is such that the setup and release times of the sensor, when combined with the physical pattern, allow a position report to be generated every 360 degrees of crank angle (degCA). MotoHawk™ always assumes that two reports should be generated

In some setups the two reports do not end up being 360degCA apart. Perhaps the half moon is not exactly a halfmoon or the setup and release times of the cam sensor are such that they introduce too much error. In such circumstances the model can choose to ignore one of the triggers. It is possible to distinguish what edge relates to what report because the reported position will still be approximately 360degCA apart and position is always reported as an absolute crank angle position.

The error could also be compensated for in order to allow the report to still be used. This is recommended because having only a single feedback point per engine cycle may lead to needing to utilize a fairly damped variable cam phaser controller.