|

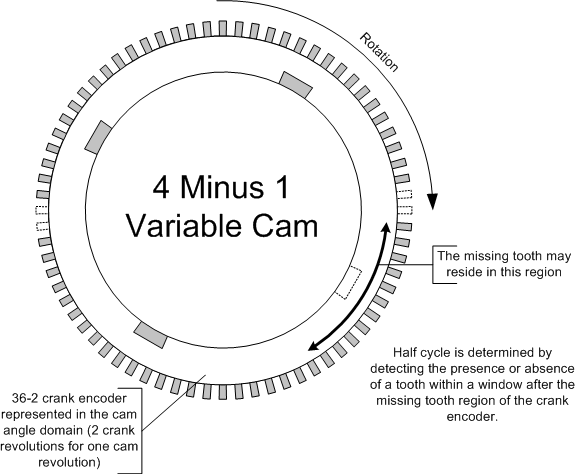

The N Teeth minus 1 Variable Cam has N equidistant teeth distributed about the wheel with one tooth missing. A cam trigger is issued each time a tooth is observed, synchronized with the edge selected in the Variable Cam Phase block.

Such patterns can be utilized by all available sensing technologies.

Those crank encoders that support a single synchronization point can utilize this variable cam configuration. The implementation is able to determine halfcycle information from a cam like this that can move relative to the crank provided the cam's missing tooth is located within a window after the crank encoder's synchronization point. The system will not operate as expected if the missing tooth does not always fall within this window for all operating conditions.

For a N Teeth with X Missing Encoder Style crank encoder this window is defined in respect to the missing tooth region.

A cam that is only being used to provide cam phaser position is not constrained by these location rules. Thus only the cam being used by the crank encoder for halfcycle information, which is nominally the cam phaser allocated on the CAM resource, would have such a restriction in a dual cam phaser system.

This cam, when used with the 36 minus 2 crank encoder, detects the halfcycle position by looking for the presence or absence of the cam's missing tooth within the 12 tooth window after the missing tooth region.